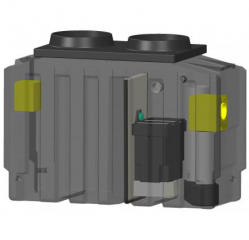

A hydrocarbon separator is intended to separate and store the free hydrocarbons contained in the runoff. The scrubber part of the device makes it possible to trap suspended matter (sands, gravel ...).

These bypass-free hydrocarbon separators equipped with a sludge trap are ideal for treating water coming from covered car parks, petrol stations, garages. For washing areas, provide a complementary V200 stripper to obtain a volume of V300.

Recall :

The oil level alarm is mandatory as additional equipment.