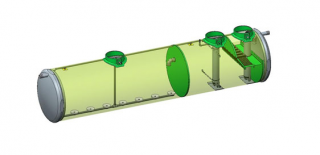

OXYMOP are compact activated sludge treatment units, developed in polyester tanks, compartmentalized into an aeration tank followed by a clarifier downstream of a rotary screen (see data sheet 6341).

Designed to treat domestic waste from 200 to 980 users, these plants use the principle of prolonged aeration with recycling and automatic extraction of settled sludge.

These stations require maintenance because of their operating principle and their property to generate excess sludge (related to bacterial growth), to eliminate.

The OXYMOP rotary sieves+ OXYMOP are designed to guarantee a discharge into superficial hydraulic medium in accordance with the decree of 22 June 2007 after a start-up period of approximately 1 month for the micro-station. This discharge to the superficial hydraulic medium is subject to authorisation by the administrative authorities.

Performance obtained *

BOD5 Less than 35 mg/l

COD Less than 125 mg/l

MES Less than 35 mg/l

These performances are obtained under normal conditions of use, care and maintenance in accordance with the instructions in this operating manual. And in the case of a biodegradable effluent whose concentrations are standard for a domestic effluent.

Note: In the case of collection of effluent from a restaurant's kitchens, a grease separator must be installed upstream of the line.

The rotary screen + oxymop must be preceded by a bar screen (can be integrated into the lifting station if it is provided for).