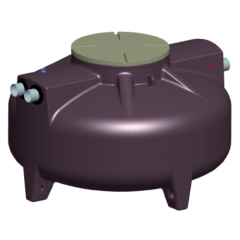

A combined fat and starch separator is an apparatus for separating and storing solids, fats and oils of animal and vegetable origin contained in greywater and for retaining peeling debris.

A starch foam spraying system is installed above the arrival of effluents from the potato peeler.

The control of the spray system must be controlled by the peeler.

A V100 sludge zone is integrated in each device.

Our devices comply with the NF EN 1825-1 standard and are CE marked.

The grease retention capacity is 40 liters per l/s